POD AND R-POD FLEX SERIES

POD AND R-POD FLEX SERIES

First introduced by Macchi in 2001, the Polyolefin-dedicated (POD) technology has become a real industrial trend since 2013, when its ability to increase the margins in the tough film market by producing thinner, stronger, better and price competitive films has been fully recognized.

Five or seven extruders have quickly become the answer to achieve the desired optical properties, printability and sealability by balancing the characteristics of the new resins which are being made available in the raw materials market, for instance compensating the excessive elasticity of metallocene or linear skins in very thin structures by using stiffer grades in dedicated layers.

Collation shrink and flexible packaging substrates have been the driving force, but new applications are being developed daily.

The POD concept, offering unprecedented possibilities of film downgauging, higher output rates and better product performances, is paving the way to new business opportunities across the film markets.

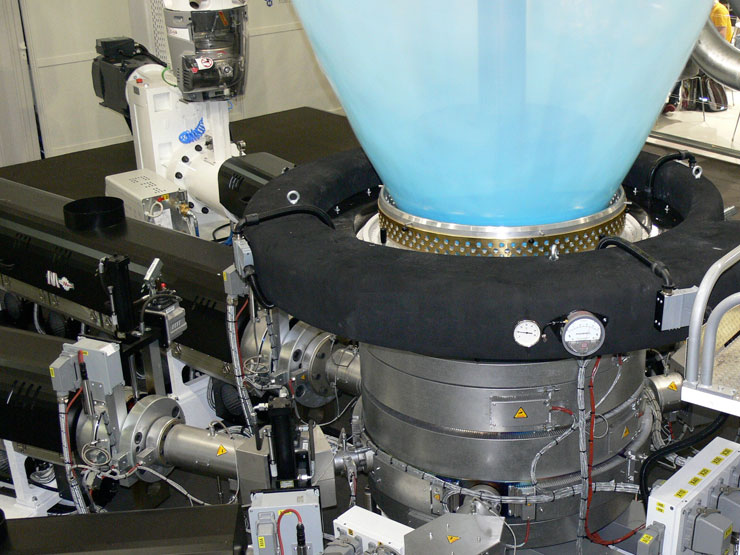

R-POD FLEX is the latest evolution of the innovative POD FLEX system (Polyolefin dedicated), specifically designed for very high productivity and for the use of "secondary" raw materials (regenerated/recycled) and is conceived for sustainable specialty films with reduced thickness, perfect sealing and excellent optical and mechanical properties.

The new R-POD FLEX line allows extremely rapid job changes and, at the same time, minimizes production wastes.

Thanks to the introduction of important developments both from the technological and automation point of view, it allows to simply from high-capacity productions for lamination films, to recycled material productions for industrial packaging.